Maintenance Master Data Management

Primezerve has an in-depth technical knowledge and expertise to prepare maintenance Master Data, Strategy, procedures for plant maintenance (PM) management requirements and implementing the best practices in equipment management, improving the equipment performance and enhancing the effectiveness of maintenance management.

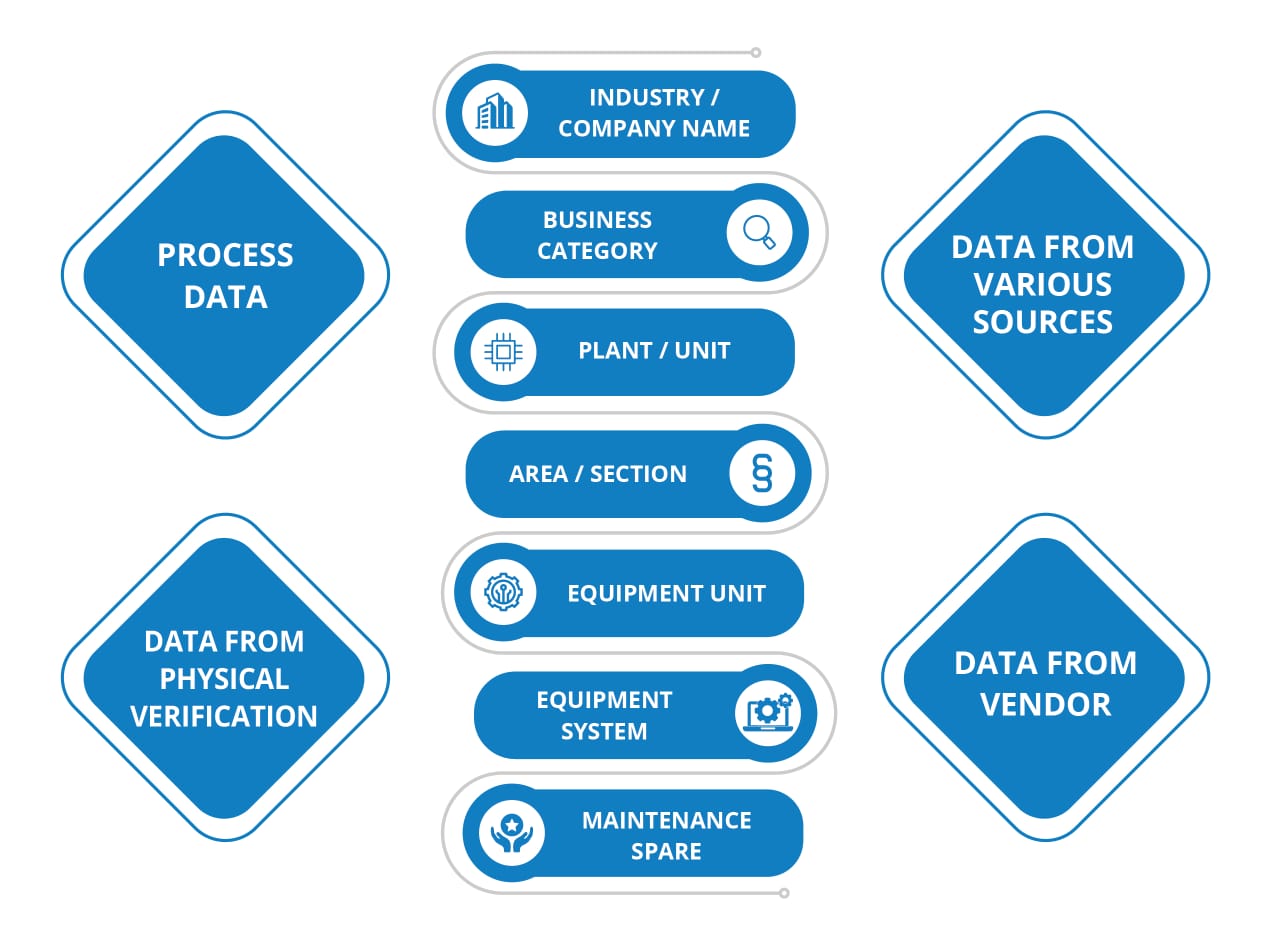

1. Plant Asset Register

It includes collection, cleansing and standardization of Equipment tags, Its specifications, Category, Superior equipment, Position, Maintenance plant, planning plant, Profit center, Cost center etc.

2. Functional Locations & Hierarchy Development

Preparation of functional location ID and Superior Equipment to track the industrial asset effectively for a better maintenance and reliability.

3. Asset Criticality

To determine the criticality of equipment, classify them into categories such as Critical, Semi-critical, and Not Critical.

4. Bill of materials development

List of raw materials, Sub-assemblies, Intermediate assemblies, Sub-components, Parts and the quantities of a system/sub system or equipment. Primezerve work with the clients to prepare the bill of material for their assets by tracking the documents, or by collecting the required information from the supplier.

5. Maintenance Plans

Preparation of a Preventive Maintenance Plan (PM), Task List, Condition Monitoring, Change over etc.

6. Failure Hierarchy

Creation of structured failure hierarchy that consists failure types, their causes, and corresponding remedies for efficient troubleshooting.

7. Plant Survey

Physical verification for Existing data review, missing data collection and As-Built Preparation of P&IDs.